Superior Sealing for Tough Conditions

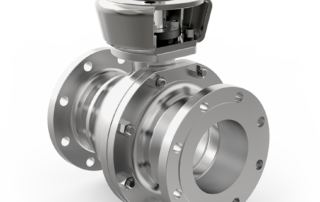

Metal Seated Floating Ball Valves

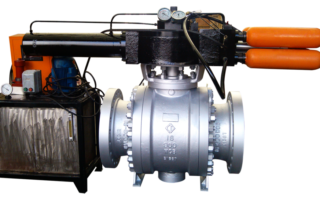

Employing the latest in processing technology and manufacturing automation, Chaoda offers high quality metal seated ball valves for service conditions where soft seats will simply not perform.

Whether it is temperature or abrasion driven, Chaoda offers a broad range of hard coatings designed for optimal performance.

Minimal moving parts with flawless execution make our floating ball valves a more suitable choice for severe applications. Full rotational surface lapping of slurry resistant scraper seats makes our metal seat ball valves the most dependable sealing valves available – at an unparalleled price point.

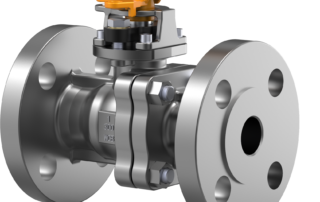

Take a Look Inside!

Superior Parts for a Superior Valve

1. Body – Designed for maximum abrasion resistance and longevity.

2. Precision Hard Surfaced Ball – Maximized sealing surface for reliable isolation.

3. Hard Surfaced Mate Lapped Seat – For a perfect seal in abrasive applications.

4. Body Seal – Endures under pressure.

5. Seat Seal Gland – Additional Leak prevention measures.

6. High Strength Spring – For a resilient loading of ball to seat.

7. Stem – High strength for maximum safety.

8. Thrust Bearing – Ensures consistent operation and packing life.

9. Graphite Stem Packing – Protects against leakage to atmosphere.

10. Packing Gland – Maximizes stem seal.

11. Gland Follower – Ensures even compression of packing.

12. ISO Mounting Bracket – Standardized to fit most actuators.

13. End Connection – Flanged connection shown below, other options available.

Dimensions & Ranges

Design Options

Refer to catalog for dimensional information.

*Consult sales team for additional sizes, pressure classes and end connections.

See More