A Backflow Preventer That Works Well In Any Situation

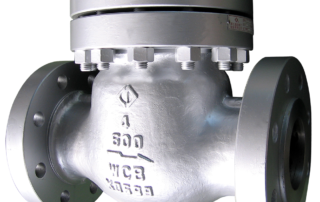

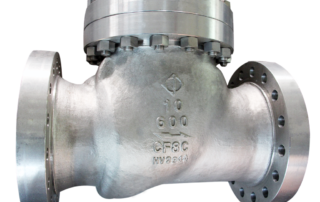

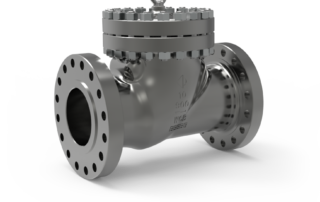

Cast Swing Check Valve

Unlike forging, casting uses the liquid form of metal to create valves. These metals are melted into a molten liquid and poured into various molds depending on the casting technology used. Chaoda has our own foundry equipped with state-of-the-art technology that allows us to pour all castings for our valves in-house including exotic alloys.

One of the biggest benefits of casting is that it can create valves with complex shapes, patterns, and sizes. Using a mold to manufacture these devices gives you more freedom to make different types valves with more intricate parts.

Complexity

For when you get exactly what you need.

One of the biggest benefits of casting is that it can create valves with complex shapes, patterns, and sizes. Using a mold to manufacture these devices gives you more freedom to make different types valves with more intricate parts.

Chaoda Swing Check Valves are the ideal choice for back flow prevention.

Dimensions & Ranges

Design Options

* Consult sales team for additional sizes, pressure classes and end connections.

See More